Understanding Bulb Connectors: The Foundation of Modern Lighting

A light bulb is useless without a way to connect it to an electrical source. This connection point, known as the bulb connectors or base, is a crucial piece of lighting technology that has evolved dramatically over the last century. Choosing the right bulb isn’t just about brightness or color; it’s about ensuring the base fits the fixture. This article will explore the history, types, and modern uses of these essential connectors.

1.0 : Introduction

The bulb connectors serves two primary functions:

- Mechanical Support: It physically holds the bulb in place within the fixture.

- Electrical Contact: It transfers power from the fixture’s socket to the bulb’s internal components (filament, LED driver, or ballast) to create light.

While the fundamental requirement is always two electrical contacts to complete a circuit (live/hot and neutral/return), the design of the base can vary widely.

2.0 : The History of Bulb Connectors

The history of the connector is tied directly to the history of the incandescent light bulb.

- Early Connectors (Pre-1880s):Initial light bulbs used cumbersome screw terminals and alligator clips, making installation difficult and dangerous.

- The Edison Screw (1880s):Thomas Edison patented the screw-in base, commonly known as the Edison Screw (ES), in the 1880s. This design was revolutionary because it was self-centering, standardized, easy to install, and provided two distinct electrical contacts: the threaded shell (neutral) and the metal tip (live).

- The Bayonet Cap (Late 1800s):Developed independently (often associated with Joseph Swan), the Bayonet Cap (BC) provided a vibration-resistant alternative, particularly useful in early industry and transportation. Instead of screwing in, the bulb is pushed in and twisted to lock into place.

These two designs the Edison Screw and the Bayonet Cap formed the foundation of residential and industrial lighting standards for over a century.

3.0 : The Evolution of Modern Connector

As lighting technology shifted from incandescent to halogen, fluorescent, and now LED, bulb bases evolved to handle new power requirements, specialized fixtures, and size constraints.

| Era | Technological Shift | Connector Evolution |

| Mid-20th Century | Halogen Lighting (Spotlights) | Bi-Pin Bases (MR16, G4):

Smaller, two-pin bases were developed to fit miniature spotlights, often requiring low-voltage power (12V). |

| Late 20th Century | Fluorescent Lighting (CFLs, Tubes) | Multi-Pin & Plug-In Bases (G24, 2G11): Complex bases with three or four pins were needed to connect to external electronic ballasts that regulate power flow in these gas-discharge lamps. |

| 21st Century | LED Lighting | Adaptation and Miniaturization: LEDs primarily adopted the legacy Edison Screw (A-type) and Bayonet standards to ensure easy retrofitting. Smaller bases like GU10 (a twist-and-lock bi-pin) became popular for specialized LED downlights. |

Table 1 : Evolution of Bulb Based Connector

4.0 : Type Of Connector

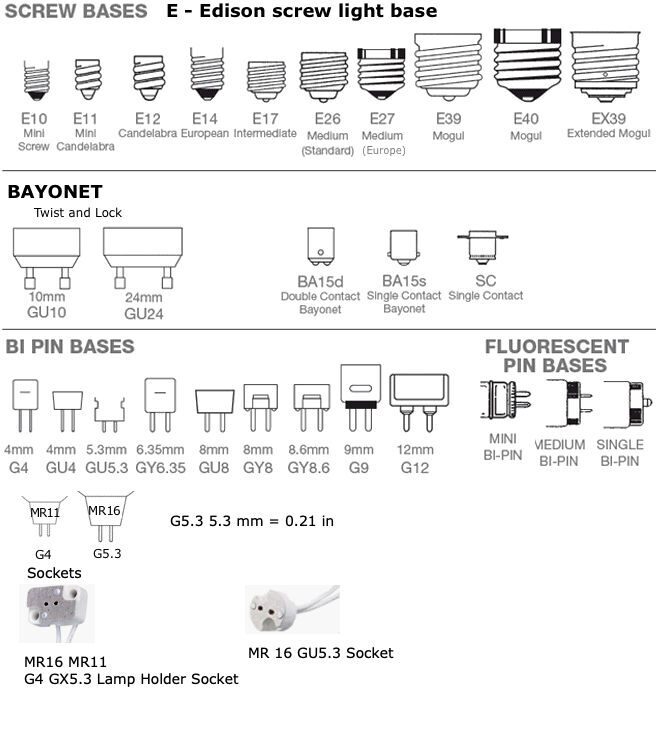

Bulb connectors are primarily categorized by their locking mechanism and the spacing/number of pins.

- Screw Bases (Edison Screw – ES)

These use a threaded cylinder. The number following the ‘E’ denotes the diameter in millimeters.

- E27 / E26: Standard home screw-in bulb connectors base (27mm / 26mm diameter).

- E14 / E12: Candelabra or small screw bulb connectors base.

- Bayonet Bases (BC)

These use two lugs that lock into the socket.

- B22: Standard home bayonet base.

- B15: Small bayonet base.

- Bi-Pin Bases (Pin-Type)

These use two or more parallel pins. The number following the letter denotes the distance between the pins in millimeters.

- GU10: Features two thick pins with feet (or lugs). Requires a push-and-twist-to-lock motion. Used primarily for high-voltage track and recessed lighting.

- MR16 / G4 / G5.3: Features two thinner pins. Installation is a simple push-in/plug-in. Often used for low-voltage accent lighting and landscaping.

- G9 / G4: Small two-pin capsules are used in decorative fixtures.

- Multi-Pin/Plug-In Bases

- G24q / 2G11:Bases with three or four pins, almost exclusively used for Compact Fluorescent Lamp (CFL) plugs, designed to interface with an external ballast.

5.0 : Differences Between Common Connectors

| Feature | Edison Screw (E27) | Bayonet (B22) | GU10 (Bi-Pin) | MR16 (Bi-Pin) |

| Locking Mechanism | Threaded (Screw-in) | Lugs (Push & Twist) | Lugs/Feet (Push & Twist) | Simple Push-in |

| Voltage | Line Voltage (120V/240V) | Line Voltage (120V/240V) | Line Voltage (120V/240V) | Low Voltage (12V) |

| Ease of Replacement | Very easy | Easy, but less common in North America | Easy, requires a twist | Very easy (simple plug-in) |

Table 2 : Differences Common Bulb Connectors

The voltage difference between GU10 (Line Voltage) and MR16 (Low Voltage) is critical. Attempting to use a low-voltage MR16 bulb directly in a line-voltage fixture will destroy the bulb and is a fire hazard unless a suitable transformer is present.

6.0 : Common Use in Industrial and Residential Setting

a) Residential Use

- E27 / B22:Used for general illumination in table lamps, ceiling pendants, and standard light fixtures.

- GU10:Dominates modern kitchen and living room recessed downlighting and track lighting, especially with LED bulbs.

- E14 / E12:Used for small chandeliers, wall sconces, and appliance bulbs.

b) Industrial and Commercial Use

- E40 / E39 (Goliath Screw):Large screw bases used for high-wattage lamps in warehouse or street lighting.

- Plug-In/Multi-Pin:Used extensively in commercial buildings for fluorescent troffer lighting (e.g., in offices and retail spaces) where energy efficiency is paramount.

- MR16 / G4:Used in display cases, museum spotlights, and landscape lighting where small, focused light is needed.

7.0 : Conclusion

From the simple, standardized design of the Edison Screw to the specialized Bi-Pin configurations required by modern spotlighting, the light bulb connectors is the unsung hero of our electrical world. Understanding the differences, especially the distinction between line-voltage GU10 and low-voltage MR16 is essential for safe and effective lighting installation, ensuring both compatibility and longevity for your fixtures.

8.0 : References

- Cowan, R. (1997). The Electrical Century. Journal of the Institution of Electrical Engineers, 13(1), 31-38.

- General Electric Lighting Technical Guides (Various Editions).

- IEC 60061 (International Electrotechnical Commission) – Standard sheets for lamp caps and holders.

- Schall, D. (2014). Lighting Retrofit and Relighting. McGraw-Hill Education.