The Unsung Hero of Automation: Understanding the Limit Switch

Ever wonder how machines know when to stop, start, or change direction?

Often, the answer lies with a simple yet indispensable component: the limit switch.

These electromechanical devices are the eyes and ears of countless automated systems, ensuring precision, safety, and reliable operation across industries.

- What Exactly is a Limit Switch?

At its core, a limit switch is a sensor that detects the presence or absence of an object and, upon detection, converts that mechanical motion into an electrical control signal. Think of it as a physical “on/off” button that a moving part presses.

- “Limit” refers to the switch’s role in defining the limit of travel or position of a machine part.

- “Switch” refers to the contacts inside that open or close an electrical circuit.

2. How It Works: The Basics?

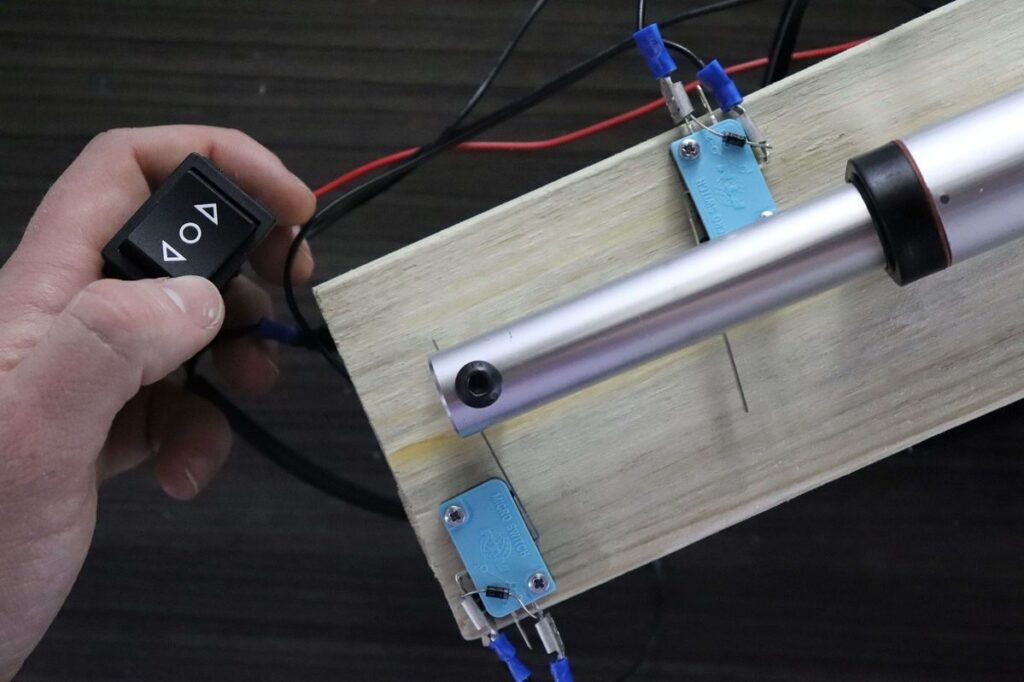

A typical limit switch consists of three main parts:

- Actuator: This is the part that makes contact with the moving object. Common types include roller levers, plungers, and wobble sticks.

- Head: Contains the mechanism that transmits the movement from the actuator to the contacts.

- Body (or Switch Unit): Houses the electrical contacts (usually a set of normally open (NO) and normally closed (NC) contacts) and the wiring terminals.

When the moving object (like a conveyor belt item or a machine carriage) physically pushes the actuator, the internal mechanism snaps the electrical contacts from one state to the other (e.g., opens a closed circuit or closes an open one).

This change in the circuit signals the control system (like a Programmable Logic Controller or PLC) to perform the next action, such as stopping a motor.

3. Where Do We Find Limit Switches?

The applications for limit switches are incredibly diverse, proving their robust utility in almost any mechanical environment:

- Machine Tools: Controlling the maximum travel distance of a drill press or mill axis.

- Conveyor Systems: Counting items, detecting jams, or signaling the end of a line.

- Elevators and Lifts: Ensuring the car stops precisely at the floor level and preventing over-travel.

- Industrial Doors and Gates: Sensing when the door is fully open or fully closed.

- Safety Interlocks: Ensuring a machine guard is in place before the machinery can operate, protecting workers.

- Packaging Machinery: Confirming a box is in position for filling or sealing.

4. Advantages Over Other Sensors

While proximity sensors and photo-electric sensors exist, limit switches offer unique benefits that keep them relevant in modern automation:

Feature Limit Switch Advantage

- Reliability

Highly robust and reliable, especially in harsh or dirty environments (dust, oil, coolant). - Simplicity

Requires no complex setup or calibration; it is purely mechanical. - Power

Can directly switch higher currents than solid-state sensors.

Positive Action provides a physical, positive confirmation of contact, making it ideal for safety circuits.

The limit switch may not be the flashiest component in an industrial setting, but its role is absolutely critical.

By translating the physical world of movement and position into actionable electrical signals, it forms a fundamental building block for accurate, safe, and efficient automated processes. It’s truly the unsung hero that ensures everything stops and starts exactly when it should.

I am perpetually thought about this, thankyou for posting.