Understanding Explosion-Protected Electrical Equipment: Essential Safety in Hazardous Areas

1.0: Introduction

Electrical Equipment systems installed in environments where flammable gases, vapors, or combustible dusts may accumulate must be specially designed to prevent becoming an ignition source. Explosion-protected equipment commonly referred to as Ex-proof is engineered so that any internal electrical fault, spark, or heat build-up cannot ignite the surrounding atmosphere. These protective measures greatly reduce the likelihood that electrical failures will trigger fires or explosions in hazardous industrial settings.(Source 1.1, 1.2, 3.7)

2.0 : Defining the Hazard: Area Classification Systems

A fundamental step in explosion protection is determining how hazardous an area is. Classification electrical equipment systems indicate how frequently explosive atmospheres may be present, which in turn dictates the level of protection electrical equipment must provide. Two major systems are used internationally: the Zone system and the Class/Division system.

3.0 : International (IECEx/ATEX) Zone System

The International Electrotechnical Commission (IEC) and the European Union’s ATEX (Atmosphères Explosibles) directives assign hazardous areas to a zone system based on how often and how long the frequency and duration of the explosive occur

(Source 1.2, 1.3, 1.4, 1.5)

- Zone 0 (Gas/Vapor) or Zone 20 (Dust):

Explosive atmospheres are present continuously or for long periods (>1,000 hours/year).

(Source 1.3)

- Zone 1 (Gas/Vapor) or Zone 21 (Dust):

Explosive atmospheres are likely to occur during normal operation (10-1,000 hours/year).

(Source 1.3)

- Zone 2 (Gas/Vapor) or Zone 22 (Dust):

Explosive atmospheres are unlikely to occur during normal operation or are present for only a short time (<10 hours/year)

(Source 1.3)

4.0 : North American (NEC) Class/Division System

The NEC system, defined in NFPA 70, categorizes hazards according to the type of material involved and the likelihood of its presence.

(Source 1.3, 1.6, 2.4)

- Class I: Hazard due to flammable gases or vapors such as hydrogen or propane. (e.g., hydrogen, propane)

(Source 1.6).

- Class II: Hazard associated with combustible dusts (e.g., grain, coal dust).

(Source 1.6).

Class III: Environments containing easily ignitable fibers or flyings.

(Source 1.3, 1.6)

4.1 : Division

- Division 1: Hazardous materials are present under normal operating conditions (Source 1.6).

- Division 2: Hazardous material appears only during abnormal conditions such as equipment failure or leaks.

(Source 1.6)

5.0 : Core Protection Techniques

Explosion protection does not rely on a single method but a combination of engineering techniques, each aligned with IEC 60079 requirements. While “explosion-proof” is often associated specifically with the Flameproof approach, several other techniques play critical roles depending on the equipment and hazard type.

(Source 1.2, 1.5, 2.4)

- Flameproof (Ex d)

A rugged enclosure is built to contain any ignition event that occurs internally, ensuring that flames or hot gases cannot ignite the hazardous atmosphere outside.

- Increased Safety (Ex e)

Electrical components are designed and constructed to prevent arcs, sparking, and excessive heat during normal operation. This method involves elevating mechanical and electrical reliability to avoid ignition sources.

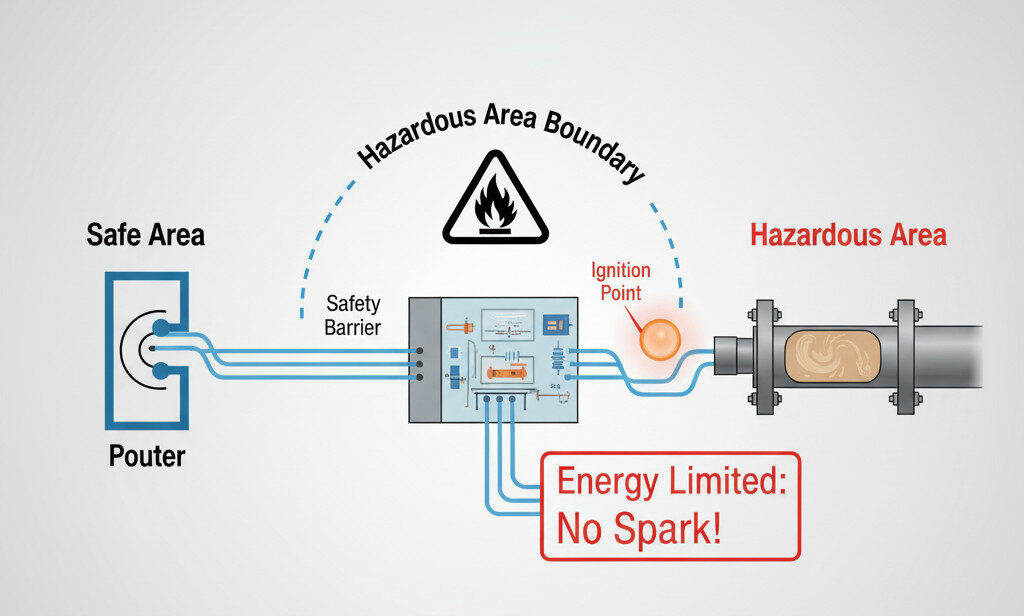

- Intrinsic Safety (Ex i)

Circuits are engineered to limit electrical and thermal energy to values incapable of igniting a hazardous atmosphere, even when faults occur. It is especially suitable for low-power devices and instrumentation.

- Pressurization (Ex p)

Clean air or inert gas is used to maintain a protective overpressure inside an enclosure so that hazardous materials cannot enter and ignite. This is effective for larger equipment such as analyzer shelters and control cabinets.

6.0 : Temperature Classification

Electrical Equipment must operate below the ignition temperature of the hazardous material present. Temperature Classes (T-Classes) specify the maximum allowable surface temperature of equipment used in explosive atmospheres.

This is indicated by the Temperature Class (T-Class):

| T-Class | Maximum Surface Temperature |

| T1 | 450°C |

| T2 | 300°C |

| T3 | 200°C |

| T4 | 135°C |

| T5 | 100°C |

| T6 | 85°C |

(Source 1.3, 2.4)

The T6 rating is the most restrictive, ensuring the surface temperature does not exceed 85°C

7.0 Certification and Marking

All explosion-protected equipment must be certified by an accredited third-party body to guarantee compliance with the relevant standards. Key global certifications include:

- IECEx: International certification system (Source 1.3).

- ATEX: Mandatory certification for equipment used in the European Union

(Source 1.4).

- UL/CSA: Common North American certifications(Source 2.2).

Certified equipment is marked with a specific code, often beginning with the “Ex” symbol (Source 1.3, 1.4, 3.5).

This markings is used to indicate the equipment type, protection method, gas or dust grouping, and temperature classification. These codes allow users to verify suitability for specific hazardous areas. (Source 1.4)

8.0 Citation List

The citations provided below are based on the globally recognized standards mentioned in the search results (IEC, ATEX).

| ID | Standard / Reference | Notes |

| 1 | IEC 60079-0 – Equipment: General Requirements | Fundamental requirements for Ex equipment |

| 2 | IEC 60079-1 – Flameproof Protection ‘d’ | Defines principles of flameproof construction |

| 3 | IEC 60079-11 – Intrinsic Safety ‘i’ | Covers intrinsically safe design criteria |

| 4 | ATEX Directive 2014/34/EU | EU framework for equipment in explosive atmospheres |

| 5 | IEC 60079-10-1/10-2 – Area Classification (Gas/Dust) | Establishes classifications for hazardous zones |

| 6 | NFPA 70 (NEC), Articles 500-506 | Defines North American Class/Division system |

| 7 | IEC 60079-7 – Increased Safety ‘e’ | Requirements to avoid arcs, sparks, and overheating |

| 8 | IEC 60079-2 – Pressurization ‘p’ | Specifies design of pressurized enclosures |

| 9 | IEC 60079-31 – Dust Ignition Protection ‘t’ | Requirements for dust-tight enclosures |

- Defining the Hazard: Area Classification Systems

| Article Statement | Quote to Use (Must be followed by citation: 5, 4, or 6) |

| Zone 0 (Gas/Vapor):

Explosive atmospheres are present continuously or for long periods. |

Zone 0:

Area subject to permanent, long-period or frequent presence of a dangerous explosive gas atmosphere. 5 |

| Zone 1 (Gas/Vapor):

Explosive atmospheres are likely to occur during normal operation. |

Zone 1:

An area in which an explosive gas atmosphere is likely to occur in normal operation occasionally. 5 |

| Zone 2 (Gas/Vapor):

Explosive atmospheres are unlikely to occur… or are present for only a short time. |

Zone 2:

A place in which an explosive atmosphere is not likely to occur in normal operation, but if it does occur, will persist for a short period only. 5 |

| NEC System:

Describes the material (Class) and the frequency (Division). |

The NEC system, described in NFPA 70, Articles 500 to 506, outlines classifications where “the division depends on the probability that they will contain flammable materials.

6 |

2. Core Protection Techniques

| Article Statement | Quote to Use (Must be followed by citation: 2, 3, 7, or 8) |

| Flameproof (Ex d): Withstands an internal explosion and prevents the spread of the flame/hot gases. | The working principle of Ex d is that the enclosure is designed to withstand an internal explosion and prevent the transmission of the explosion to the external environment.”

2 |

| Intrinsic Safety (Ex i): Limits electrical and thermal energy to a level insufficient to cause ignition. | The method limits electrical and thermal energy to levels incapable of causing ignition even in fault conditions.

3 |

| Increased Safety (Ex e): Focuses on preventing sparks, arcs, or excessive temperatures. | Ex e protection provides additional measures [to] ensure reliable prevention of unacceptably high temperatures and sparks or electrical arcs.

7 |

| Pressurization (Ex p): Maintains an internal pressure of a protective gas to prevent entry of the explosive atmosphere. | Pressurization is a Segregation principle that prevents the hazardous atmosphere from entering equipment.

8 |

References

- ^ IEC 60079-0: Explosive atmospheres – Part 0: Equipment – General requirements. International Electrotechnical Commission (IEC). Latest Edition.

- ^ IEC 60079-1: Explosive atmospheres – Part 1: Equipment protection by flameproof enclosures ‘d’. International Electrotechnical Commission (IEC). Latest Edition.

- ^ IEC 60079-2: Explosive atmospheres – Part 2: Equipment protection by pressurized enclosures ‘p’. International Electrotechnical Commission (IEC). Latest Edition.

- ^ IEC 60079-7: Explosive atmospheres – Part 7: Equipment protection by increased safety ‘e’. International Electrotechnical Commission (IEC). Latest Edition.

- ^ IEC 60079-11: Explosive atmospheres – Part 11: Equipment protection by intrinsic safety ‘i’. International Electrotechnical Commission (IEC). Latest Edition.

- ^ IEC 60079-10-1: Explosive atmospheres – Part 10-1: Classification of areas (Gas). International Electrotechnical Commission (IEC). Latest Edition.

- ^ NFPA 70: National Electrical Code (NEC), Articles 500-506. National Fire Protection Association (NFPA). Latest Edition.

- ^ Directive 2014/34/EU (ATEX). European Union. 2014.

- ^ Dietz Electric. “Hazardous Location Motors.” Retrieved

Further reading

- McMillan, Alan. Electrical Installations in Hazardous Areas. Butterworth-Heineman, 1998. ISBN 0-7506-3768-4.

- Schram, Peter. Electrical Installations in Hazardous Locations. Jones and Bartlett, 1997. ISBN 0-87765-423-9.

- A Practitioner’s Handbook for potentially explosive atmospheres. The Engineering Equipment and Materials Users Association, 2017. ISBN 978-0-85931-222-6.